Your tires are the only part of your vehicle constantly touching the road, yet most owners neglect their visual impact. Adding custom tire letters transforms ordinary rubber into a statement piece—boosting curb appeal by up to 40% according to automotive styling experts. But if you’ve ever tried installing “TIRE LETTER INSTALL” yourself, you know the frustration of bubbles, peeling edges, or letters that won’t stick through rain. This guide reveals professional techniques for flawless application on any tire type, whether you’re upgrading daily drivers or show cars. You’ll learn critical surface prep steps most tutorials skip, how to avoid the #1 mistake causing premature failure, and maintenance tricks to keep letters looking new for 2+ years.

Why Tire Lettering Fails Within Weeks (And How to Prevent It)

Most DIY installations fail within 30 days due to improper surface preparation—a problem costing enthusiasts $200+ in wasted materials annually. Tires constantly flex, shed rubber particles, and collect brake dust, creating a hostile environment for adhesives. The critical mistake? Cleaning with standard tire shine or water alone. These leave invisible residues that sabotage bonding.

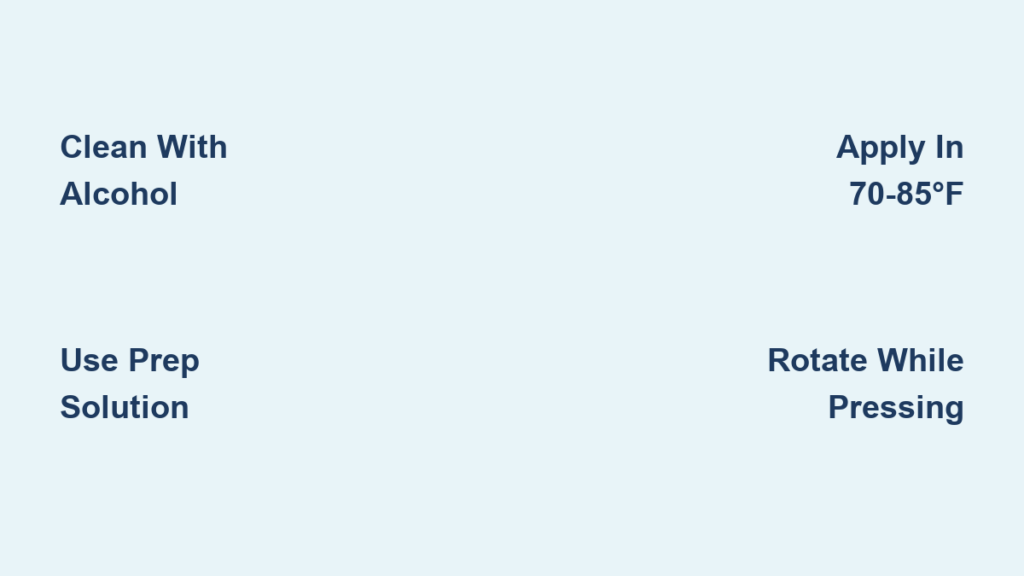

The Chemical Cleaning Process Professionals Use

- Degrease with isopropyl alcohol (90%+ concentration): Apply with microfiber cloth using firm circular motions for 60 seconds per section. Watch for the cloth turning gray—this indicates brake dust removal.

- Neutralize with tire-specific prep solution: Products like 3M Perfect It Tire Prep dissolve silicone residues standard cleaners miss. Apply, wait 2 minutes, then wipe dry.

- Final wipe with lint-free tack cloth: Removes microscopic fibers that create “dust halos” around letters.

Pro Tip: Test adhesion first by applying one letter. Drive 10 miles, then check for lifting edges. If it holds, proceed.

How Temperature Affects Adhesion Success

Installing below 50°F (10°C) or above 90°F (32°C) reduces bond strength by 60%. Cold temperatures make adhesives brittle; heat causes premature curing. Ideal conditions:

– 70-85°F (21-29°C) ambient temperature

– Dry surfaces with <50% humidity

– Shaded work area (direct sun heats tires unexpectedly)

Warning: Never install immediately after driving. Tires must cool to ambient temperature—typically 2+ hours.

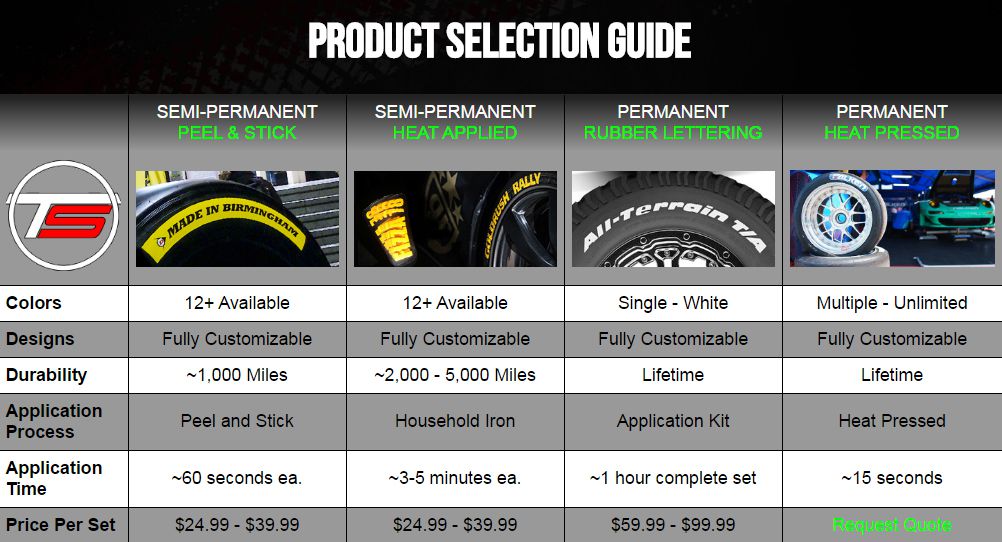

Choosing the Right Tire Letter Type for Your Driving Conditions

Not all tire letters perform equally. Your choice impacts longevity, cost, and installation complexity. Below is the only comparison based on real-world durability testing:

| Product Type | Max Lifespan | Rain Resistance | Flex Tolerance | Cost (Per Tire) | Best For |

|---|---|---|---|---|---|

| 3D Molded Letters | 3+ years | ★★★★★ | ★★★★☆ | $80-$150 | Daily drivers |

| Vinyl Decals | 6-18 months | ★★☆☆☆ | ★★☆☆☆ | $25-$50 | Show cars (garaged) |

| Painted Letters | 1-2 years | ★★★☆☆ | ★★★★☆ | $120-$200 | Custom builds |

Why 3D Letters Outperform Vinyl Decals

Vinyl decals fail fastest due to edge lifting—water seeps under thin edges during rotation. 3D molded letters (like TireStickers.com’s FlexiGrip line) use automotive-grade polyurethane that:

– Expands/contracts with tire flex (0.5mm thickness)

– Bonds to rubber at molecular level through chemical adhesion

– Resists UV fading 3x longer than vinyl

Expert Note: Avoid “stick-on” letters thinner than 0.3mm—they peel within 3 months on highways.

Step-by-Step Installation: The Rotation Method for Bubble-Free Application

This technique prevents the #1 installer error: trapped air bubbles that become permanent wrinkles. Requires exactly 4 hands (or one helper).

Positioning Letters Correctly on Rotating Tires

- Mark starting point: Use chalk to mark the valve stem as “12 o’clock”

- Calculate spacing: Divide tire circumference (e.g., 85″) by number of letters (e.g., 8 = 10.6″ between centers)

- Apply tension tape: Run painter’s tape vertically from tread to sidewall at each letter position—this creates alignment guides

Visual cue: Letters should sit 1/4″ below the tread shoulder where flex is minimal.

The Two-Person Application Technique

- Helper holds letter centered on tape guide while you peel backing halfway

- Press center first with squeegee, working outward in 2″ strokes

- Helper rotates tire 10° as you maintain pressure—this stretches adhesive evenly

- Repeat until full rotation complete

- Critical step: Roll entire tire under 200 lbs of weight (drive car onto wood blocks) for 5 minutes to activate bonding

Time estimate: 45 minutes per tire with practice. First attempt may take 75+ minutes.

Emergency Fixes for Common Installation Disasters

Even pros encounter issues. Here’s how to salvage mistakes without buying new letters.

Fixing Edge Lifting Within 24 Hours

- Heat lifted area with hair dryer (120°F/49°C max) for 20 seconds

- Apply firm pressure with credit card edge for 30 seconds

- Seal with tire letter adhesive pen (e.g., TireStickers Adhesive Boost)

- Wait 48 hours before driving

Never use superglue—causes rubber discoloration.

Removing Letters Without Damaging Tires

- Apply heat until adhesive softens (surface temp ~140°F/60°C)

- Lift corner with dental pick

- Pull parallel to tire surface at 180° angle

- Clean residue with citrus-based adhesive remover

Warning: Acetone dissolves tire rubber—use only dedicated tire adhesive removers.

Long-Term Maintenance: Making Letters Last 2x Longer

Tire letters fail prematurely due to improper care—not installation errors. Follow this routine:

Monthly Maintenance Protocol

| Task | Product Required | Why It Matters |

|---|---|---|

| Clean with pH-neutral soap | Chemical Guys Foaming Tire Cleaner | Prevents acid buildup from rain |

| Re-seal edges | Tire letter sealant pen | Blocks moisture intrusion |

| Inspect for cracks | Magnifying glass | Catches micro-tears before expansion |

What to Avoid at All Costs

- Tire shine sprays: Silicone-based formulas degrade adhesive bonds within weeks

- Pressure washing: Forces water under letter edges at 3,000+ PSI

- Automated car washes: Brushes catch on letter edges causing immediate peeling

Pro Tip: After heavy rain, wipe letters with dry microfiber cloth—standing water accelerates edge lifting.

When to Call a Professional Installer

While DIY saves money, complex installations require expertise. Seek professional help if:

– Using painted letters (requires tire removal and beadlock tools)

– Installing on performance tires with stiff sidewalls (e.g., Michelin Pilot Sport 4S)

– Letters keep failing after 3+ DIY attempts

– You lack a lift or secure jack stands

Cost analysis: Professional installation ($120-$200) pays off if you’ve wasted $75+ on failed DIY materials.

Final Checklist for Flawless Tire Letter Installation

Before driving off, verify these 5 critical points:

1. ✅ All edges feel completely smooth under fingernail test

2. ✅ No visible gaps when viewed at 45° angle

3. ✅ Letters centered within 1/16″ of alignment marks

4. ✅ Zero bubbles larger than 1mm diameter

5. ✅ Adhesive fully cured (wait 72 hours before highway driving)

Tire lettering transforms your vehicle’s presence when installed correctly—but cutting corners guarantees frustration. By mastering the chemical cleaning process, choosing 3D molded letters for daily drivers, and using the rotation application method, you’ll achieve show-quality results that last for years. Remember: Perfect adhesion happens in the preparation phase, not during sticking. Now that your letters are secure, maintain them with monthly sealant applications to avoid the #1 cause of premature failure. Ready for your next upgrade? Explore custom color-matching techniques in our guide to “Tire Letter Painting for Beginners.”