Ever wonder why your steering wheel starts vibrating at highway speeds? That annoying shake isn’t just uncomfortable—it’s a clear signal that your wheels need proper balancing. When your tires are correctly balanced, you experience a vibration-free ride with even tire wear and minimal stress on suspension components. But when imbalance exists, centrifugal forces generated at higher speeds create those familiar shakes that make driving unpleasant and potentially unsafe. Understanding how does tire balancing work helps you recognize warning signs early and appreciate why this critical maintenance service matters for both comfort and vehicle longevity.

Tire balancing addresses fundamental physics principles that affect every rotating wheel assembly. As your vehicle moves, any uneven mass distribution creates periodic forces that translate into vibration throughout the chassis. These forces intensify dramatically with speed—doubling your speed quadruples the imbalance forces due to centrifugal force principles. Modern balancing equipment precisely measures these imbalances and calculates exactly where to place counterweights to neutralize the heavy spots. The process combines both static and dynamic balancing techniques to eliminate vibration sources completely, ensuring your wheels rotate smoothly at any speed. By the end of this guide, you’ll recognize imbalance symptoms, understand the balancing process, and know when to seek professional service.

Why Your Wheels Develop Imbalance and How to Spot It

Wheel imbalance occurs when the mass distribution within your tire and wheel assembly isn’t perfectly centered around the axle. This uneven weight distribution creates centrifugal forces during rotation that manifest as steering wheel vibration, seat oscillation, or whole-vehicle shaking. The vibration typically starts around 50-60 mph and intensifies as speed increases, making highway driving particularly uncomfortable when imbalance exists.

Understanding Mass Distribution in Your Wheel Assembly

Your tire and wheel combination must have its center of mass aligned precisely with the axle centerline for proper balance. Manufacturing variations inevitably create minor inconsistencies—some sections of the tire may contain slightly more rubber, while wheel casting might have microscopic density differences. When mounted together, these small variations compound, creating heavy spots that require correction weights. Even a small imbalance of just 1/2 ounce can generate over 6 pounds of force at 55 mph, explaining why seemingly minor imbalances cause noticeable vibration.

Recognizing Imbalance Symptoms by Location

Front wheel imbalance typically produces steering wheel vibration that increases with speed, while rear wheel issues often create seat or floorboard shaking. Pay attention to when the vibration occurs: imbalance vibration appears at specific speeds and intensifies as you accelerate, whereas brake pulsation only happens during braking. Some drivers describe rear imbalance as a “floating” sensation at highway speeds. If you notice uneven tire wear patterns developing—particularly cupping or scalloping—this often indicates underlying imbalance that’s accelerating tire deterioration.

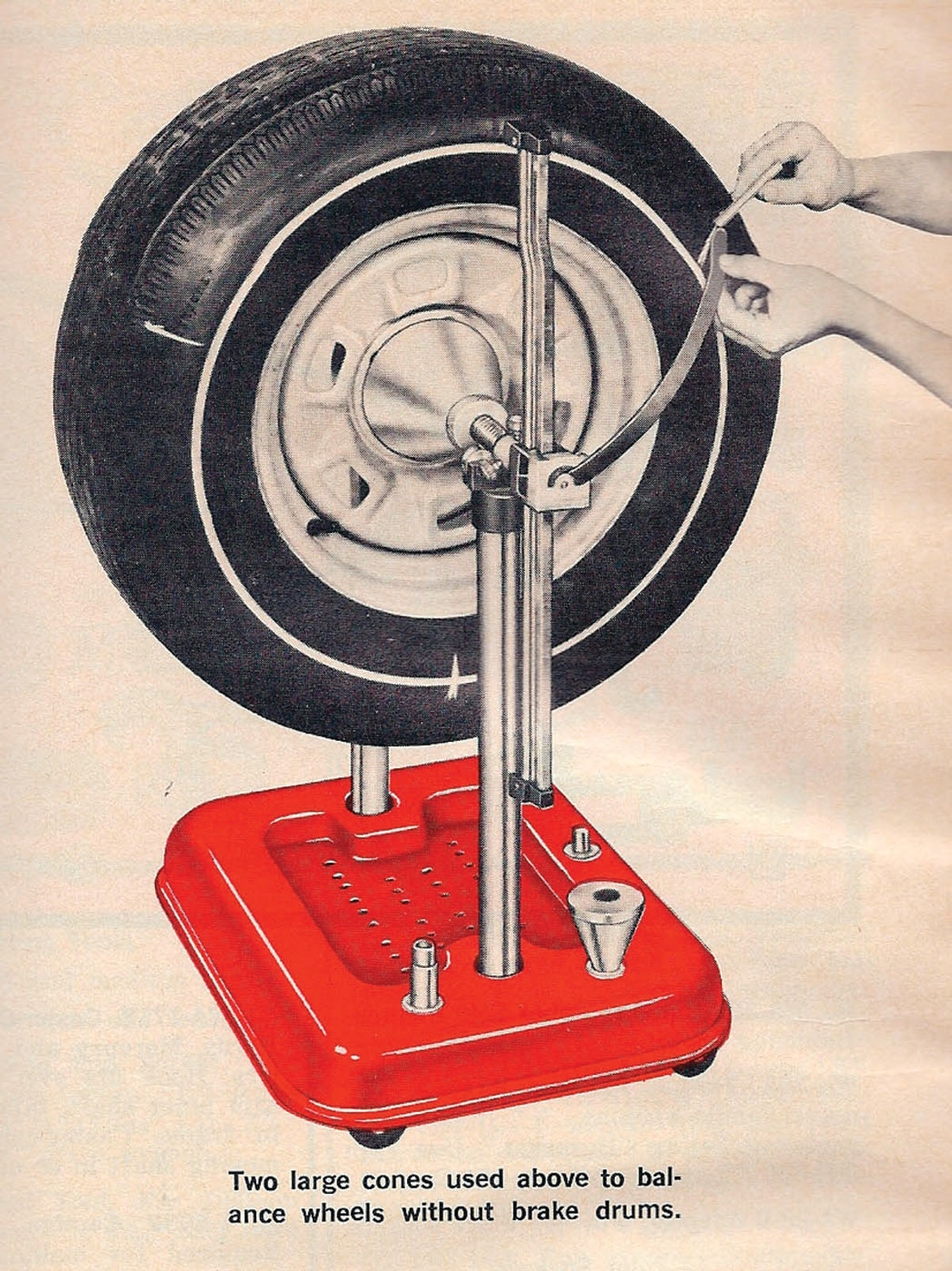

Static Balancing: Correcting the Vertical Forces

Static balancing addresses the most fundamental aspect of wheel imbalance—ensuring the wheel’s center of mass aligns with the rotation axis when viewed from the side. This process corrects vertical forces that cause up-and-down vibration but doesn’t address lateral forces that create side-to-side shaking. While modern shops use computerized equipment, understanding static balance principles helps you appreciate what technicians are measuring.

How Gravity Reveals Imbalance

During static balancing, technicians mount your wheel assembly on a vertical spindle. If the center of mass isn’t perfectly centered on this axis, gravity causes the assembly to rotate until the heavy spot settles at the bottom. The amount of force required to prevent this rotation indicates imbalance severity, while the angular position reveals where the heavy spot exists. Early static balancers used bubble gauges to show this imbalance, but today’s equipment measures deflection electronically with far greater precision.

Professional Static Balance Measurement Process

Modern shops use computerized balancers that spin your wheel assembly briefly to measure the forces generated. The equipment calculates exactly how much weight to add and precisely where to place it for optimal correction. Technicians typically apply weights to the outer rim edge for most wheels, though some specialty wheels require weights on both inner and outer flanges. This initial static correction eliminates the most obvious vibration sources before addressing more complex dynamic imbalances.

Dynamic Balancing: Eliminating Lateral Shake

Dynamic balancing addresses the more complex issue of lateral forces that cause side-to-side vibration. A wheel can be statically balanced yet still create uncomfortable shaking because mass distribution along the wheel’s width creates twisting forces during rotation. This is why both static and dynamic balancing are essential for complete vibration elimination.

How Moment of Inertia Affects Your Ride

Dynamic imbalance occurs when the wheel’s principal moment of inertia axis doesn’t align with the rotation axis. Imagine two equal heavy spots positioned at opposite ends of your wheel’s width—they balance statically but create a twisting couple when rotating. This couple generates lateral forces that manifest as steering wheel shake distinct from the up-and-down vibration of pure static imbalance. Only by addressing both planes of imbalance can technicians eliminate all vibration sources.

Precision Testing for Complete Balance

Professional technicians measure dynamic imbalance by spinning your wheel assembly at controlled speeds (typically 100-300 RPM) while sensitive sensors detect forces in multiple planes. The computerized equipment resolves these measurements into static and couple components for both inner and outer wheel planes, calculating exact weight placement for complete correction. This two-plane correction ensures your wheels rotate smoothly without generating forces in any direction, providing the vibration-free ride you expect.

Common Causes of Sudden Wheel Imbalance

Understanding what causes wheel imbalance helps prevent problems and recognize when service is needed. Some causes develop gradually through normal wear, while others occur suddenly through impact or damage. Knowing these sources helps you address the root cause rather than just treating symptoms.

Gradual Imbalance From Normal Wear

Uneven tire wear gradually shifts mass distribution as tread depth varies across the tire’s circumference. This wear might result from improper alignment, suspension issues, inconsistent inflation, or aggressive driving. A shift of the tire on the rim—where the bead moves relative to the wheel flange—also creates imbalance even when both components were originally balanced. Regular tire rotation helps distribute wear evenly and prevents these gradual imbalance issues.

Sudden Imbalance Triggers

Counterweights breaking loose is a common cause of sudden vibration—corrosion, impact, or vibration itself can cause weights to detach. Foreign material like road tar, embedded stones, or winter ice/snow packed in wheel wells adds rotating mass that throws off balance. Collision damage from potholes or curbs can deform wheels, shifting mass distribution dramatically. If you hit something substantial or notice sudden vibration, have your wheels inspected immediately for damage that might require more than simple rebalancing.

Tire Balancing vs. Wheel Alignment: Critical Differences

Many drivers confuse these services, but they address fundamentally different issues. Tire balancing corrects mass distribution within the rotating assembly to eliminate vibration, while wheel alignment adjusts angular relationships between wheels to ensure proper tracking and even tire wear.

What Alignment Actually Fixes

Wheel alignment adjusts three critical angles: camber (wheel tilt viewed from front), caster (steering axis angle), and toe (whether wheels point slightly inward or outward). Misalignment causes uneven tire wear patterns—excessive negative camber wears inside shoulders, while incorrect toe accelerates wear across the entire tread. While alignment problems don’t typically cause vibration, the resulting uneven wear can eventually create imbalance issues.

Why Both Services Matter for Long Tire Life

New tires should receive both balancing and alignment checks for optimal performance. Balancing ensures smooth rotation from day one, while proper alignment prevents uneven wear that would gradually create imbalance. Most manufacturers recommend alignment checks every 6,000 miles or annually, while balancing should occur whenever tires are mounted, after impact damage, or when vibration symptoms appear. This comprehensive approach maximizes tire life and ensures comfortable operation throughout your tires’ service life.

Preventing Imbalance: Maintenance Tips You Can Do

Proper tire care significantly extends the time between balancing services and prevents many common imbalance issues. These simple maintenance steps help maintain smooth operation and maximize tire longevity.

Monthly Maintenance Checklist

Check tire pressures monthly using a quality gauge—underinflated tires wear unevenly, creating imbalance over time. Inspect balance weights for missing or loose clips, particularly after winter driving when road salt accelerates corrosion. Remove debris like stones embedded in tread grooves that can throw off balance. During winter months, clear ice and snow from wheel wells immediately after driving in severe weather—frozen clumps create significant imbalance that disappears once melted.

Recognizing When to Seek Professional Service

Steering wheel vibration that increases with speed is the clearest sign you need balancing service. Uneven tire wear patterns visible during routine inspection also indicate potential imbalance issues. If you’ve recently had new tires installed, experienced a significant impact, or notice vibration returning shortly after balancing, schedule professional service immediately. Most technicians recommend balancing tires every 5,000-6,000 miles as preventive maintenance, especially if you frequently drive on rough roads.

Final Note: Properly balanced wheels aren’t just about comfort—they protect your suspension components, extend tire life, and contribute to safer handling. By understanding how does tire balancing work and recognizing early warning signs, you can address issues before they escalate into costly repairs. When vibration appears, don’t ignore it—schedule professional balancing service to restore smooth operation and protect your investment. Regular maintenance now prevents expensive problems down the road, keeping your vehicle running smoothly mile after mile.