When your semi truck’s tires don’t match the correct dimensions, you’re risking premature wear, dangerous handling issues, and costly downtime that eats into your bottom line. Commercial truck tires follow specific sizing conventions that directly impact safety, fuel efficiency, and operational costs for fleets of all sizes. Understanding these dimensions isn’t just technical knowledge—it’s a critical component of fleet management that affects everything from compliance to driver safety. This guide breaks down the exact measurements, sizing systems, and application-specific requirements you need to select the right tires for every axle position on your commercial vehicles.

Standard Semi Truck Tire Sizes

The commercial trucking industry relies on a handful of standardized tire dimensions that fit most Class 8 trucks and trailers. Understanding these standards helps simplify replacement decisions and inventory management while ensuring optimal performance across your fleet.

22.5-Inch Rim Diameter: The Industry Standard

The 22.5-inch rim diameter represents the overwhelming majority of semi truck tires across North America. This standard emerged decades ago and now dominates new vehicle manufacturing and replacement tire markets. Tires with this rim diameter offer an optimal balance of load capacity, heat dissipation, and availability. You’ll find 22.5-inch tires in virtually every truck stop, service center, and tire warehouse across the country.

Within the 22.5-inch category, three primary section widths exist. The 11R22.5 width measures approximately 11 inches across the tire’s sidewall and works commonly on steer axles. The 12R22.5 offers slightly wider section width at about 12 inches, providing enhanced load distribution for certain applications. The 295/75R22.5 represents a metric designation that translates to roughly 11.8 inches section width with a 75% aspect ratio, making it extremely popular for regional and long-haul applications. When properly inflated, these tires deliver an overall diameter of approximately 41 inches, providing the right balance of ground clearance and stability for highway operations.

24.5-Inch Rim Diameter: Heavy-Duty Applications

While less common than 22.5-inch sizes, 24.5-inch rim diameters serve specific heavy-duty applications. These larger wheels typically appear on dump trucks, heavy haulers, and specialized equipment requiring maximum load capacity. The 11R24.5 and 12R24.5 represent the primary sizes in this category. Fleet managers choosing this option should verify wheel well clearance and brake clearance, as these tires significantly increase overall diameter compared to standard sizes.

The 24.5-inch tires typically measure 43-45 inches in overall diameter when new, which affects speedometer calibration and drivetrain stress if not properly accounted for during installation. These tires often feature reinforced sidewalls and deeper tread depths to handle the increased stresses of severe service applications. When selecting 24.5-inch tires, always confirm compatibility with your vehicle’s suspension geometry and brake system to prevent premature component failure.

Decoding Tire Size Designations

Commercial truck tire size designations follow specific patterns that communicate critical information about the tire’s dimensions and capabilities. Learning to read these codes empowers better purchasing decisions and ensures proper fitment for your specific application.

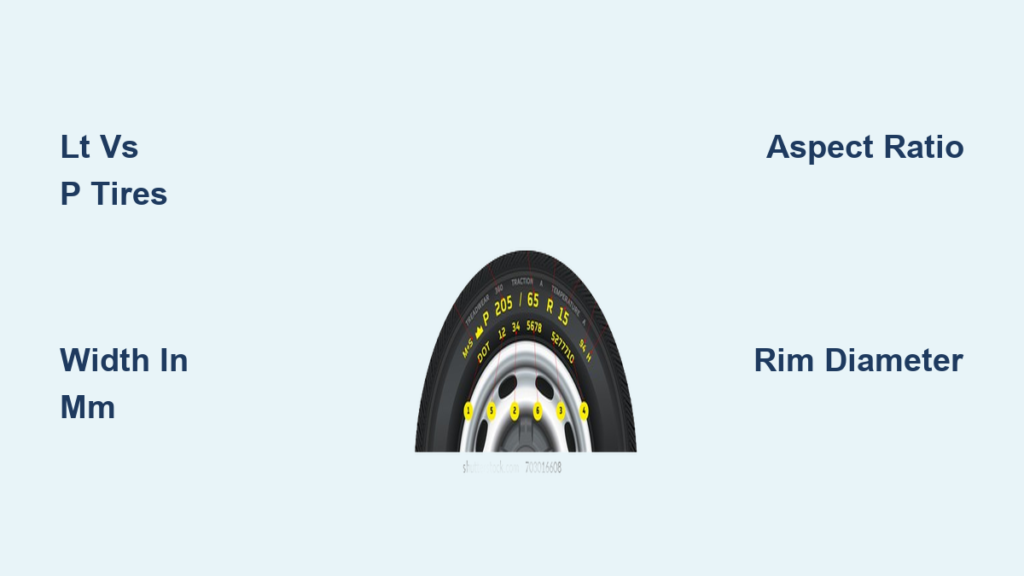

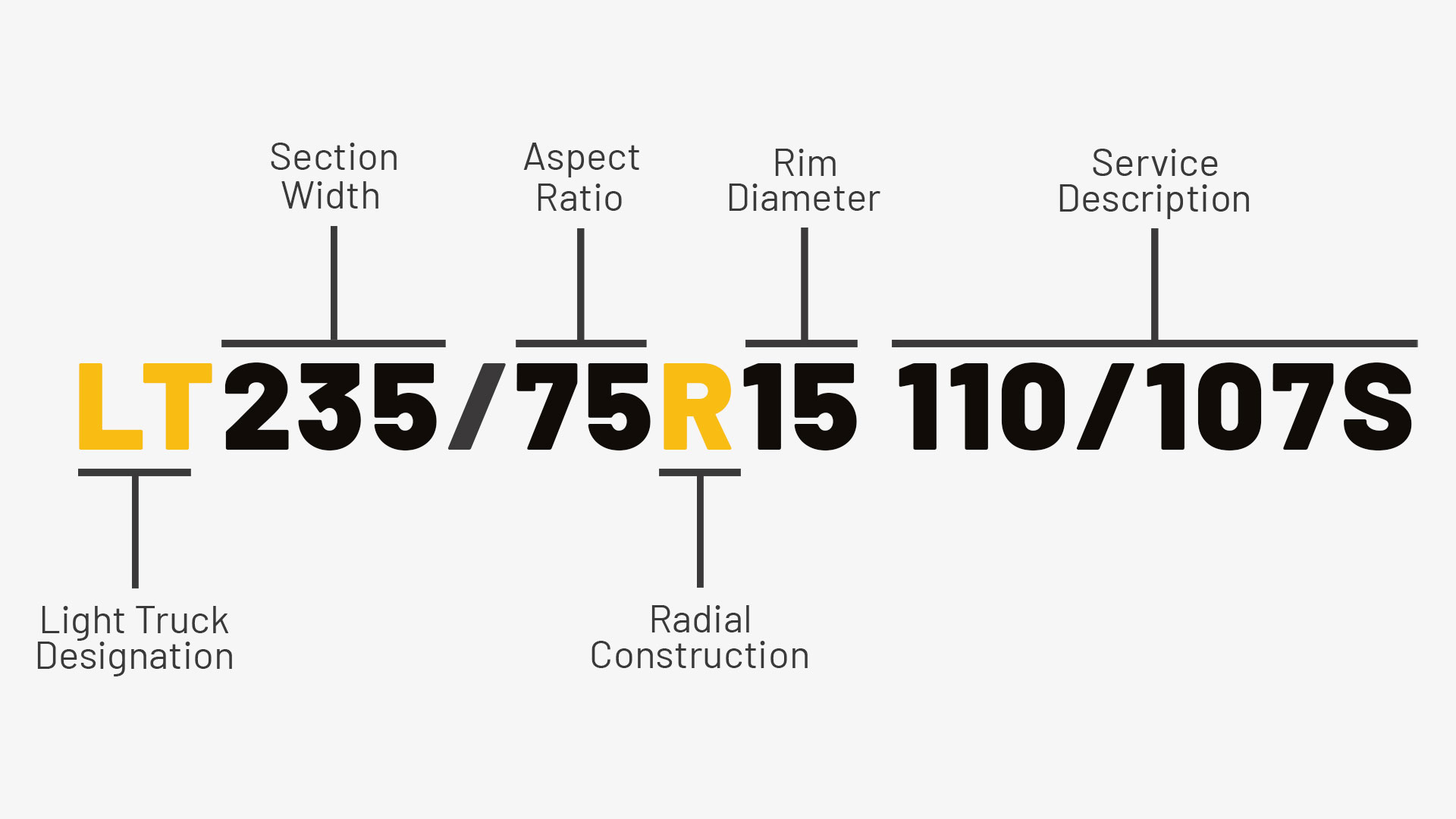

Numeric Designations (American System)

The traditional American sizing system uses a three-part format: section width, aspect ratio, and rim diameter. Consider the example 11R22.5. The number “11” indicates the tire’s section width in inches when mounted and inflated but not loaded. The letter “R” confirms radial construction, which has virtually replaced bias-ply tires in commercial applications due to superior heat dissipation and fuel efficiency. The “22.5” specifies the rim diameter in inches that the tire is designed to fit.

Pro Tip: When comparing tires across manufacturers, always verify actual measured dimensions rather than relying solely on size designations. Some brands run slightly larger or smaller than others despite using identical size markings.

Metric Designations (European System)

The metric system uses a different format that many manufacturers now adopt for international consistency. A tire marked 295/75R22.5 communicates the section width in millimeters (295mm), followed by the aspect ratio as a percentage (75), then the construction type (R for radial), and finally the rim diameter (22.5 inches).

Converting between systems helps when comparing tires across brands. The 295/75R22.5 closely approximates the 11R22.5 in overall dimensions, though the metric tire typically offers slightly more section width and a lower aspect ratio sidewall. This can affect handling characteristics and should be considered when switching between sizing systems. When in doubt, consult your tire dealer with the specific applications and operating conditions to ensure proper selection.

Steer Axle Tire Dimensions

Steer tires face unique demands because they handle steering forces while supporting significant front-axle weight. Dimension selection for this position directly impacts handling, ride quality, and driver comfort during long hours on the road.

Common Steer Tire Sizes

The 11R22.5 dominates steer axle applications across the trucking industry. This size provides an overall diameter of approximately 41 inches when new, offering good ground clearance while maintaining stable handling characteristics. Most major manufacturers—including Michelin, Bridgestone, Goodyear, and Continental—offer premium steer tires in this size with various tread compounds for different service applications.

The 12R22.5 serves applications requiring slightly higher load capacity or wider footprint. This size increases section width by approximately one inch and overall diameter by roughly 1.5 to 2 inches. Fleet managers must verify adequate clearance in the wheel well, particularly when the suspension reaches full jounce, to prevent tire-to-fender contact. This size is particularly popular among heavy haul operators and those running in mountainous regions where additional traction and load capacity matter.

Steer Tire Diameter Considerations

Overall diameter matters significantly for steer axle applications because mismatched diameters between steer and drive axles can cause drivetrain binding, irregular wear on drive tires, and degraded handling. When replacing steer tires, maintaining consistency with drive tire overall diameter ensures proper operation of the vehicle’s differential and suspension geometry.

Warning: Never mix different size tires on the steer axle—this creates dangerous handling characteristics and uneven wear patterns that compromise safety. Always replace steer tires in pairs to maintain balanced handling.

Drive Axle Tire Dimensions

Drive axle tires transmit power to the road while supporting substantial weight and handling significant torque loads. Dimension selection for this position emphasizes traction, durability, and heat management during acceleration and braking cycles.

Standard Drive Tire Sizes

The 11R22.5 serves as the most common drive axle size, matching steer tire dimensions for fleet standardization. This consistency simplifies inventory management and ensures predictable handling characteristics. Premium drive tires in this size offer advanced tread compounds designed for long tread life and even wear patterns across the drive axle positions.

The 295/75R22.5 metric size matches the 11R22.5 in overall diameter while offering slightly different handling characteristics. The wider section width distributes load across more surface area, potentially extending tread life in certain applications. Many fleets standardize on this metric size for consistency across their entire operation, especially when operating in international markets where metric sizing predominates.

Dual Spacing and Clearance

Drive axle tires must maintain proper spacing between dual assemblies to ensure adequate heat dissipation and prevent uneven wear. Standard 11R22.5 tires on 8.25-inch rim widths typically provide approximately 12 to 15 inches between tire centers when properly inflated. This spacing allows sufficient airflow between tires to prevent heat buildup during extended operation.

Insufficient dual spacing causes the inner tire to run significantly hotter than the outer tire, leading to accelerated wear on the inner position and potential premature failure. Check dual spacing during routine maintenance—especially after wheel service—to ensure proper clearance. If you notice excessive inner tire wear, spacing issues should be your first diagnostic check.

Trailer Tire Dimensions

Trailer tires support pure load without transmitting power, making their dimension requirements distinct from steer and drive positions. Proper sizing ensures adequate load capacity and appropriate handling characteristics during highway operation.

Common Trailer Tire Sizes

The 295/75R22.5 dominates trailer applications across the North American trucking industry. This size provides an overall diameter matching steer and drive tires in standard configurations, ensuring consistent trailer ride height and proper coupling with fifth wheels and landing gear. The metric designation offers slightly wider section width than the 11R22.5, providing enhanced load distribution for trailer axle positions.

The 11R22.5 also serves trailer applications, particularly for fleets seeking complete dimensional consistency across all axle positions. This approach simplifies spare tire inventory and ensures predictable handling when trailers experience crosswind or emergency maneuvering. When selecting trailer tires, prioritize long-wearing compounds designed specifically for trailer applications—they differ significantly from drive axle tread designs.

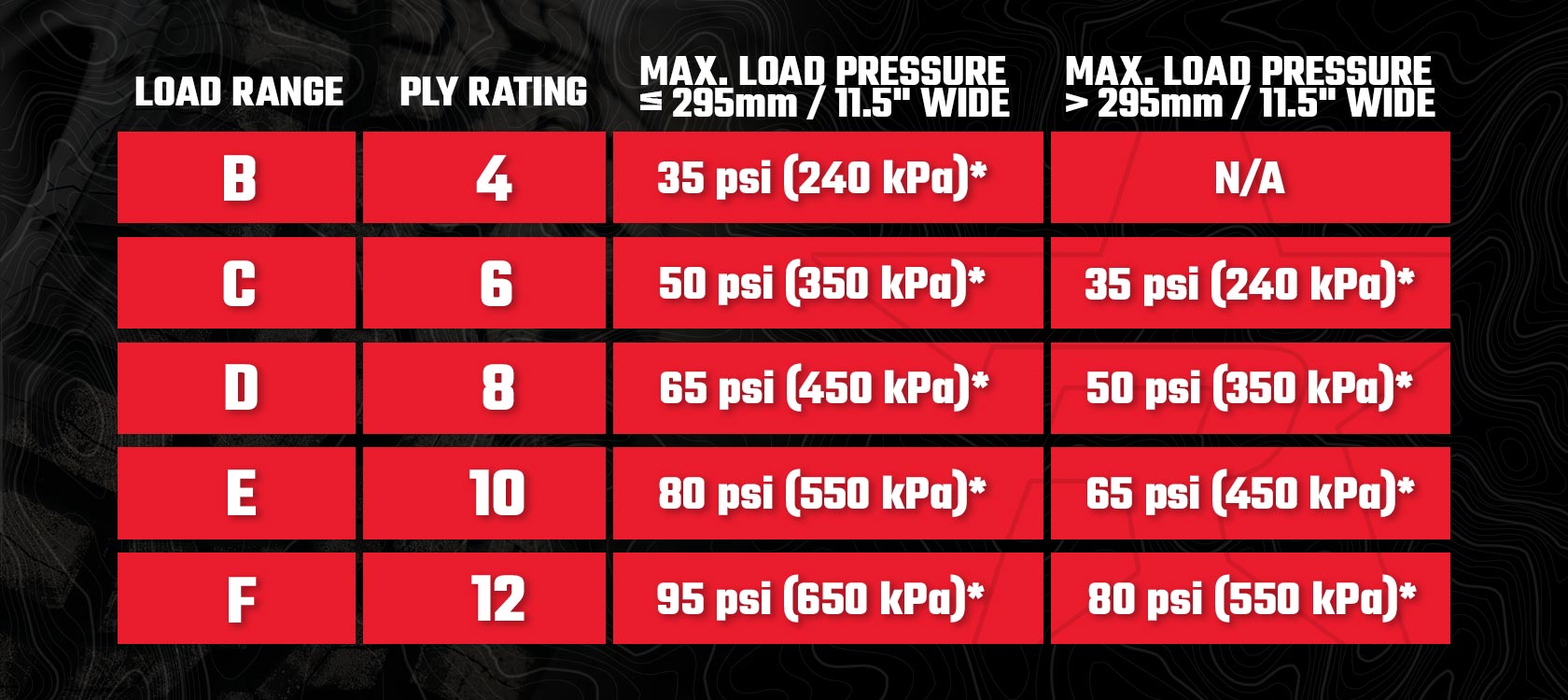

Load Range and Ply Rating Considerations

Load range designations communicate a tire’s inflation requirements and maximum load capacity at that inflation pressure. Understanding these designations ensures proper load carrying ability and prevents premature failures that could strand your truck.

Load Range Designations Explained

Modern commercial truck tires use load range letters (G, H, L, M, N) instead of explicit ply ratings, though the terminology often references historical ply construction. Load range G corresponds approximately to 14-ply construction, H to 16-ply, L to 18-ply, and M to 20-ply construction. These are nominal designations—the actual internal construction may vary based on the manufacturer’s design.

Higher load range tires require higher inflation pressures to achieve their maximum load capacity. A Load Range H tire might require 110 psi inflation for maximum load, while a Load Range G tire in the same size achieves maximum load at 95 psi. These inflation requirements affect handling, ride quality, and fuel economy, making appropriate selection important for overall fleet efficiency.

Matching Dimensions Across Axle Positions

Maintaining dimensional consistency across axle positions ensures proper vehicle dynamics, prevents drivetrain damage, and promotes even wear across all tire positions—saving you money on premature replacements.

Diameter Matching Requirements

The drive axle tires should match the steer axle overall diameter within approximately one-half inch to prevent differential binding and irregular wear. When steer tires wear down more quickly than drive tires—as is common in many applications—periodic rotation helps maintain diameter matching and extends overall tire life.

Trailer tires should match drive and steer tire diameters when possible to ensure proper coupling height and consistent handling. Mismatched trailer tire diameters can cause trailer instability during cornering and emergency maneuvers, particularly at highway speeds. Before installing new tires, measure the overall diameter of existing tires to ensure proper matching with replacements.

Final Thoughts on Semi Truck Tire Dimensions

Understanding semi truck tire dimensions empowers better purchasing decisions, improves fleet efficiency, and ensures safe vehicle operation. The 22.5-inch rim diameter dominates the industry, with section width and aspect ratio variations accommodating different load requirements and performance priorities. Proper dimension selection requires matching tire specifications to actual operating loads, axle configurations, and application requirements.

Regular maintenance including inflation monitoring, rotation, and visual inspection extends tire life and prevents premature failures. When replacing tires, maintaining dimensional consistency across axle positions ensures proper vehicle dynamics and prevents drivetrain stress. For specialized applications, consulting with tire manufacturers or qualified distributors helps identify optimal dimensions for specific operational requirements. The investment in understanding semi truck tire dimensions pays dividends through improved fuel economy, extended tire life, enhanced safety, and reduced downtime.