That confusing string of letters and numbers on your truck tire’s sidewall holds the key to finding the perfect replacement—but most drivers have no idea what it means. When you’re standing in a tire shop trying to decipher “LT245/75R16” while the clock ticks, understanding truck tire measurements becomes critical. This guide cuts through the confusion with practical decoding methods you can apply immediately, ensuring you never buy the wrong tires again. You’ll learn exactly how to read each component of your tire size notation so you can make informed purchasing decisions that match your truck’s specific requirements and your driving needs.

Most truck owners only think about tire measurements when replacement time arrives, yet this knowledge directly impacts safety, performance, and your wallet. Using incorrectly sized tires can lead to speedometer inaccuracies, reduced fuel efficiency, compromised handling, and even dangerous blowouts under load. By mastering truck tire measurements, you gain control over one of the most important safety components on your vehicle while avoiding costly mistakes that could void your warranty or insurance coverage. Let’s transform that mysterious sidewall code into actionable information you can use today.

How to Read Truck Tire Size Codes in 30 Seconds

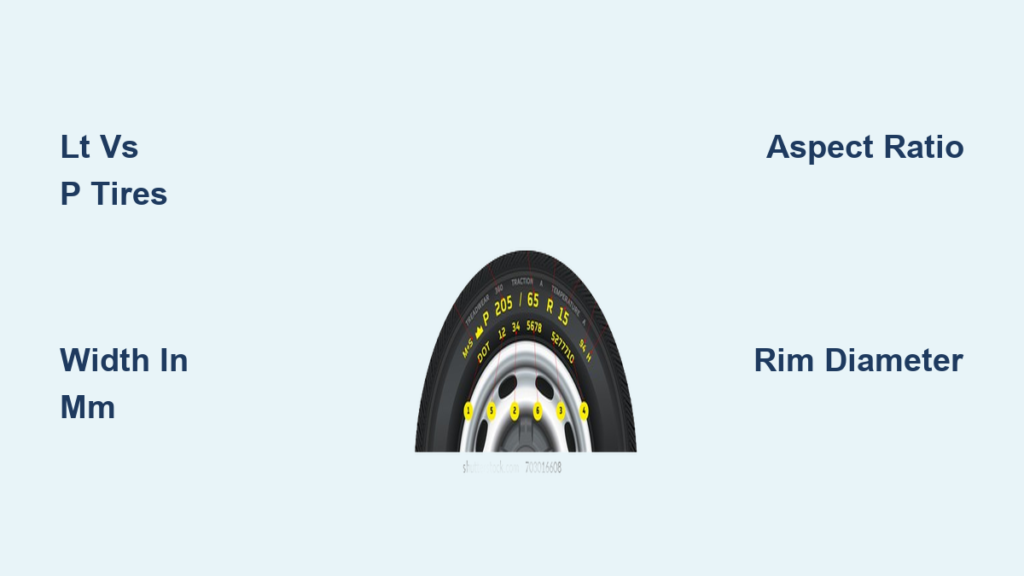

Every truck tire carries a standardized size code molded into its sidewall that reveals critical specifications at a glance. This alphanumeric sequence follows a precise format that communicates width, aspect ratio, construction type, and rim diameter—all essential factors for proper fitment and performance. Knowing how to decode this information eliminates guesswork and prevents dangerous mismatches between your tires and wheels.

Breaking Down the LT245/75R16 Example

Take the common truck tire size “LT245/75R16” as your practical decoding example. The “LT” prefix indicates this is a Light Truck tire specifically engineered for heavier loads and more demanding conditions than passenger vehicle tires. The “245” represents the tire’s width in millimeters, measured from sidewall to sidewall at its widest point when properly mounted and inflated. This measurement directly affects your truck’s stability and traction capabilities on various surfaces.

Why Each Number Determines Your Truck’s Performance

The “75” in the size designation refers to the aspect ratio—meaning the sidewall height equals 75% of the tire’s width. Higher aspect ratios provide more cushioning for heavy loads but may reduce cornering stability. The “R” signifies radial construction, the industry standard that delivers superior heat resistance and longer tread life for truck applications. Finally, the “16” indicates the tire fits a 16-inch diameter wheel—getting this measurement wrong creates dangerous mounting issues and improper clearances.

LT vs P: Critical Differences Truck Owners Must Know

Choosing between LT and P-designation tires represents one of the most consequential decisions in your truck tire selection process, with serious implications for safety and performance. Light Truck (LT) tires feature reinforced sidewalls and higher ply ratings specifically engineered to handle the additional stresses of heavy payloads, towing, and off-road conditions. Passenger (P) tires lack these reinforcements and can fail catastrophically when subjected to typical truck workloads.

When LT Tires Become Non-Negotiable for Safety

If your truck regularly carries heavy cargo, tows trailers, or ventures off paved roads, LT tires aren’t just recommended—they’re essential for maintaining structural integrity under load. The reinforced construction of LT tires allows them to sustain higher air pressures without deforming, which directly translates to better weight distribution and reduced risk of heat-related failures during extended highway driving. Never substitute P-metric tires for LT specifications on a vehicle designed for light truck applications.

The Hidden Danger of Mismatched Tire Classifications

Using P-metric tires on a truck designed for LT tires creates multiple safety hazards you might not immediately recognize. These include excessive sidewall flexing under load that generates dangerous heat buildup, reduced load-carrying capacity that could lead to sudden failures, and altered handling characteristics that compromise control during emergency maneuvers. Always match the tire classification on your replacement tires exactly to what’s specified for your truck model.

Truck Tire Width Measurements and Their Real Impact

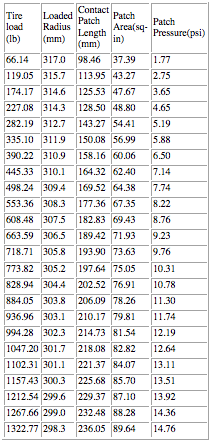

The width measurement in your truck tire size (like the “245” in LT245/75R16) represents the tire’s section width in millimeters when mounted on the manufacturer-recommended wheel width. This dimension directly influences your truck’s contact patch—the area actually touching the road—which affects traction, stability, and even fuel economy. Wider tires generally provide better grip but require more power to rotate, potentially reducing your miles per gallon.

How Width Affects Your Truck’s Handling Characteristics

A tire that’s too narrow for your truck’s weight distribution creates excessive pressure on a small contact patch, leading to accelerated center tread wear and reduced traction in wet conditions. Conversely, tires that are too wide may not flex properly during cornering, causing unpredictable handling and potential clearance issues with suspension components. For most half-ton trucks, widths between 245mm and 285mm offer the best balance of performance, comfort, and efficiency.

Finding Your Ideal Width for Specific Driving Needs

Work trucks hauling heavy loads benefit from slightly wider tires (265mm-285mm) that distribute weight more effectively across the contact patch. If you primarily drive on paved roads with minimal cargo, narrower tires (235mm-255mm) might improve fuel economy without sacrificing safety. Always verify that your chosen width maintains proper clearance from wheel wells and suspension components—measure at full compression to avoid rubbing issues that destroy tires prematurely.

Aspect Ratio Secrets Every Truck Owner Should Know

The middle number in your truck tire size (the “75” in LT245/75R16) represents the aspect ratio—a percentage that calculates sidewall height relative to tire width. This seemingly small number dramatically impacts your truck’s ride quality, load capacity, and handling characteristics. Higher aspect ratios (75-85) create taller sidewalls that absorb road imperfections better and provide additional cushioning for heavy payloads.

High vs Low Aspect Ratios: Performance Trade-offs

Trucks used for heavy hauling or off-road adventures benefit from higher aspect ratios (75+) that provide more flexible sidewalls capable of absorbing impacts from rough terrain. These taller sidewalls also create a larger air chamber that helps support heavy loads without excessive pressure increases. Performance-oriented trucks or those with larger wheels often use lower aspect ratios (65 or less) for improved cornering response and stability at high speeds, though with a firmer ride.

Calculating Actual Sidewall Height from Aspect Ratio

To determine your tire’s actual sidewall height in inches, multiply the width (in millimeters) by the aspect ratio percentage, then convert to inches. For an LT245/75R16 tire: 245 × 0.75 = 183.75mm, which equals approximately 7.23 inches of sidewall height. This measurement helps you understand how much cushioning your tire provides and whether it will maintain proper clearance with your truck’s suspension components.

Radial Construction: Why “R” Matters More Than You Think

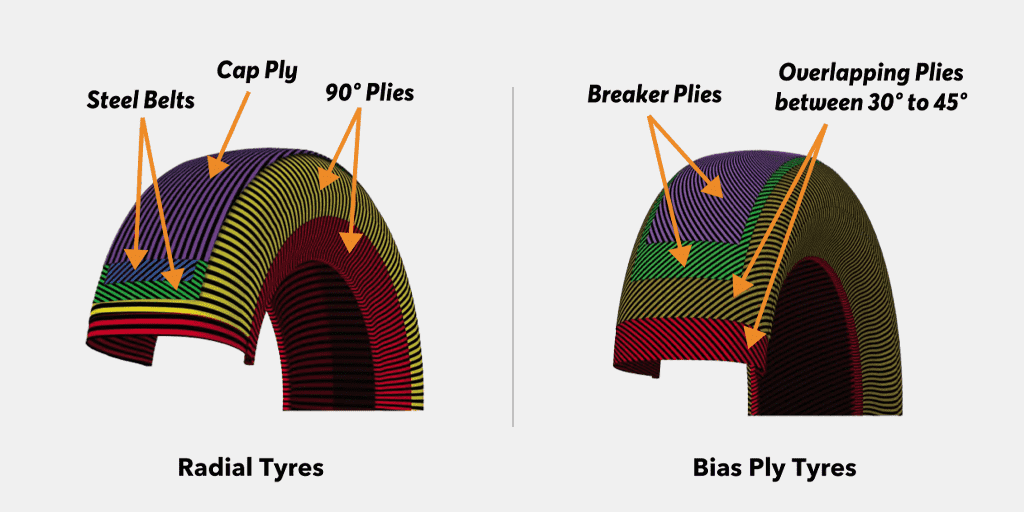

The “R” in your truck tire size (LT245/75R16) signifies radial construction—the dominant tire technology that revolutionized the industry with its superior performance characteristics. Radial tires feature steel belts running perpendicular to the direction of travel, creating a stable footprint that dissipates heat effectively and provides consistent traction across various conditions. Virtually all modern truck tires use radial construction due to its significant advantages over older bias-ply designs.

How Radial Design Enhances Truck Tire Durability

Radial construction allows the tire tread to remain flatter against the road surface during rotation, creating more even wear patterns that extend tire life—especially important for trucks that accumulate high mileage. The flexible sidewalls of radial tires absorb road shocks without transferring excessive vibration to your truck’s frame, reducing driver fatigue on long hauls. This design also generates less internal heat during operation, a critical factor for trucks carrying heavy loads over extended distances.

Spotting Non-Radial Tires and When They Might Be Appropriate

Some specialty truck tires, particularly for severe off-road applications or vintage vehicles, may use bias-ply construction (indicated by a “D” instead of “R”). These tires feature crisscrossed ply layers that create a stiffer sidewall capable of withstanding extreme punctures at lower pressures. However, for most modern trucks used in typical conditions, radial tires provide superior safety, comfort, and longevity. Always verify construction type matches your driving requirements before purchasing.

Rim Diameter Requirements: Getting the Fit Exactly Right

The final number in your truck tire size (the “16” in LT245/75R16) specifies the wheel diameter in inches—a measurement that must match your truck’s wheels precisely for safe operation. This dimension determines how the tire mounts to the wheel and creates an airtight seal. Using a tire with an incorrect rim diameter creates immediate safety hazards including improper bead seating, air leaks, and potential tire detachment during operation.

Common Truck Rim Sizes and Their Applications

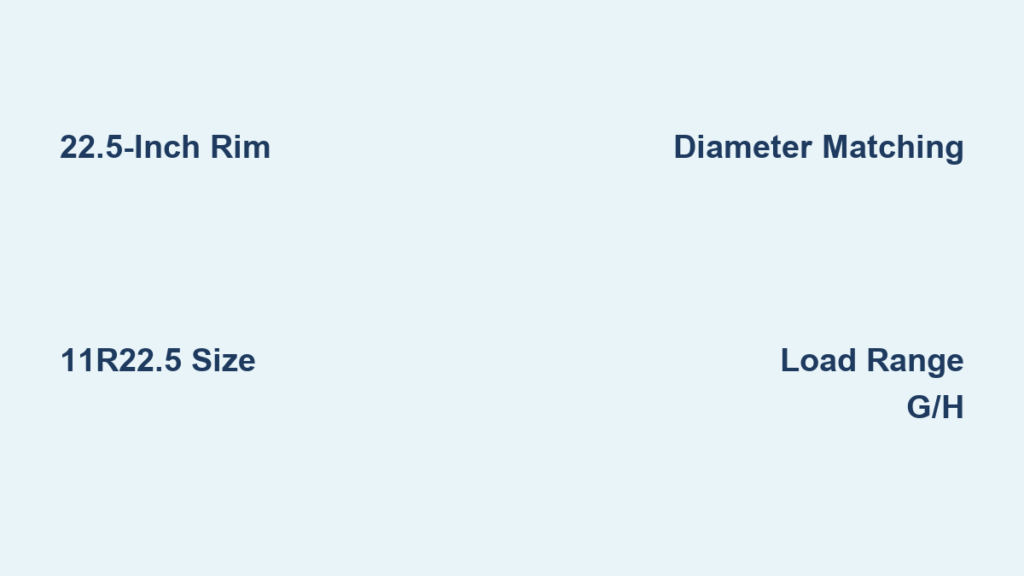

Light truck tires come in rim diameters ranging from 14 inches (common on compact trucks and older models) up to 22 inches (found on modern luxury trucks and SUVs). Most full-size pickup trucks use 17- or 18-inch wheels as standard equipment, while commercial trucks often stick with 16- or 17-inch configurations for durability and cost-effectiveness. Always match the rim diameter exactly—no exceptions—as even a half-inch difference creates dangerous mounting issues.

What Happens When Rim Diameter Doesn’t Match

Mounting a 16-inch tire on a 17-inch wheel creates an immediate safety hazard as the tire bead cannot properly seat against the wheel flange, leading to air leaks and potential sudden deflation. Conversely, attempting to mount a larger diameter tire on a smaller wheel requires excessive stretching that damages the tire’s internal structure and creates weak spots prone to blowouts. Never compromise on rim diameter matching—it’s a non-negotiable safety requirement.

Where to Find Your Exact Truck Tire Measurements

Locating your truck’s correct tire size requires checking multiple reliable sources to verify accuracy before purchasing replacements. The most authoritative reference is the tire information placard mounted inside the driver’s side door jamb, which displays the manufacturer’s recommended specifications for your specific truck configuration. This placard provides the exact size, load range, and inflation pressure required for optimal performance and safety.

Checking the Driver’s Side Door Jamb Placard

Open your driver’s door and examine the vertical door frame for a permanently affixed sticker containing tire size information. This placard specifies the exact tire size your truck was engineered to use, along with critical details like maximum load capacity and proper inflation pressures. Never ignore this information—even if you’ve previously installed different tires, the placard represents what your truck’s suspension and braking systems were designed for.

Reading Sidewall Markings on Current Tires

The tires currently mounted on your truck display their complete size designation molded into the sidewall, typically beginning with “LT” for light truck applications. Locate this information on the outer sidewall where it appears as a continuous sequence like “LT245/75R16.” While this shows what’s currently installed, verify it matches the door jamb placard to ensure previous owners haven’t installed incorrect sizes that could compromise safety.

Avoid These 5 Common Truck Tire Measurement Mistakes

Truck owners frequently make critical errors when interpreting tire measurements that lead to safety hazards and unnecessary expenses. The most dangerous mistake involves ignoring load range information (indicated by letters like C, D, or E after the size), which specifies the tire’s maximum weight capacity at proper inflation. Using tires with insufficient load range for your truck’s GVWR (Gross Vehicle Weight Rating) creates immediate safety risks and potential tire failures.

Mistake #1: Overlooking Speed Rating Requirements

Many truck owners focus solely on physical dimensions while ignoring the speed rating symbol (like “S” or “T”) that indicates maximum safe operating speed. While trucks rarely reach high speeds, this rating affects the tire’s structural integrity and heat resistance—critical factors during highway driving with heavy loads. Always ensure your replacement tires meet or exceed the original speed rating specified for your truck.

Mistake #2: Assuming All “LT” Tires Are Equal

Not all Light Truck tires deliver the same performance characteristics despite sharing the “LT” prefix. LT tires come in different service descriptions that affect load capacity, with options ranging from LT245/75R16/C (6-ply equivalent) to LT245/75R16/E (10-ply equivalent). The higher load ranges (D and E) are essential for heavy-duty applications like towing or commercial hauling where standard LT tires would be overloaded.

Understanding truck tire measurements puts you in control of one of your vehicle’s most critical safety components. By decoding each element of your tire size notation—LT designation, width measurement, aspect ratio, construction type, and rim diameter—you ensure proper fitment and performance for your specific truck and driving needs. Always verify specifications using your door jamb placard and current tire markings before purchasing replacements.

Maintain your tires properly by checking inflation monthly (when cold) and rotating them every 5,000-7,000 miles to maximize tread life. If you frequently haul heavy loads, consider upgrading to higher load range tires that match your actual usage patterns rather than standard replacements. When in doubt about proper truck tire measurements for your vehicle, consult a reputable tire specialist who can cross-reference your truck’s specifications with available tire options to guarantee safe, optimal performance. Your safety and your truck’s longevity depend on getting these measurements exactly right.